Spring tide surges, everything is rejuvenated. From March 26th to 28th, the Munich Shanghai Electronic Production Equipment Exhibition was held at the Shanghai New International Expo Center. As a professional platform for future electronic technology innovation and technology exchange, the exhibition gathers the entire electronic manufacturing industry chain, including wire harness processing and connector manufacturing, system level packaging, electronic manufacturing automation, industrial robots, motion control, etc., comprehensively showcasing various innovative products and hardcore technologies in the electronic manufacturing industry chain.

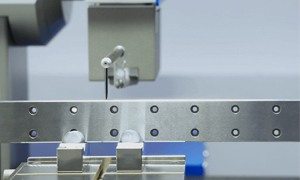

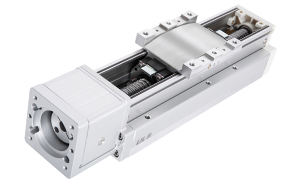

At the exhibition site, Xinxin Linear Precision Machinery (Suzhou) Co., Ltd. (hereinafter referred to as "Xinxin Linear") attracted many professional visitors to stop and observe a high rigidity and high-precision display machine in the exhibition area. The display machine is equipped with two 15N parallel ULS slides, each slide is equipped with four 15NS ULS sliders. The two platforms are respectively equipped with an automatic pencil with a 0.5mm lead core and an automatic pencil with a lead-free core. The linear motor drives the slide table to move in opposite directions at a speed of 2m/s, so that the lead core pen can be accurately inserted into the lead-free core pen and the lead core is continuous.

This linear guide may seem ordinary, but it can achieve precise linear reciprocating motion of objects under high-speed motion. It is an important component of high-end manufacturing equipment such as industrial CNC machine tools, semiconductor manufacturing devices, robots, medical devices, etc., supporting every small and critical movement in the production process.

In addition, multiple innovative products such as micro linear guides, standard linear guides, and embedded linear modules showcase their high precision, high speed, and high rigidity at zero distance; The corrosion-resistant modules developed for photovoltaic panel assembly lines can adapt to complex working conditions... The core products and solutions showcased by Xinxin Linear fully reflect its years of focus on cutting-edge technology and innovative practices in the field of transmission, gathering multiple core achievements such as multi axis linkage control technology and customized transmission systems, providing perfect and effective linear motion application solutions from design to systematic production, showcasing its extraordinary technological strength and innovative vitality from multiple dimensions.

Strive for excellence, break through barriers and monopolies

The production transformation of high-end precision transmission industry transformation and upgrading, with linear guide rails as the core pivot, is taking place in the production workshop of Kunshan Xinxin Linear Precision Machinery (Suzhou) Co., Ltd., 100 kilometers away from the exhibition.

Entering the grinding production workshop, an intelligent production scene comes into view. More than 20 micro rail internal and external grinding equipment are performing high-precision grinding on the linear guide slider that has just passed the base surface grinding. On site workers are conducting online detection of the center distance and bead groove arc shape of the semi-finished products to ensure that the processing accuracy of each product is in the 1 micron level, which is equivalent to controlling its accuracy within 1% of a hair thread, and its surface roughness is controlled to be less than 0.2 microns.

How to turn the micrometer level precision of a product from a drawing into reality within a square inch? Cao Jianye, the Operations Director of Xinxin Linear Precision Machinery (Suzhou) Co., Ltd., vividly revealed the core password for the continuous and stable maintenance of high precision products with the phrase "embroidering on hair strands": "For example, heat treatment is like 'doing SPA' on steel, and the performance will change if the temperature difference exceeds 5 ℃; the equipment in the grinding workshop must be supported by a reinforced concrete independent foundation; the temperature in the workshop is maintained at 25 ± 3 ℃ all year round... but these are just the foundation, the real secret is to polish every parameter like tuning a piano

Cao Jianye stated that in order to ensure the stability and interchangeability of products, starting from the cold drawing of raw steel coils, more than 20 precision processes such as drilling, heat treatment, and straightening are required to form micrometer level precision products. Each step requires careful consideration and a complete set of continuous and strict testing and inspection before entering the grading and packaging stages. The entire process tests the high-precision processing technology and management level of the equipment.

Xinxin Linear is constantly seeking innovation and change, breaking through barriers and surpassing others, and developing into a leader in the field of linear transmission, reflected in its "Chinese chip", "Chinese solution" and "Chinese speed" that promote industrial technology upgrading and value creation.

Many high-end equipment factories around the world now use our 'Chinese chips', especially for medical testing equipment and semiconductor precision process assembly lines. Zhao Hui, Business Director of Xinxin Linear Precision Machinery (Suzhou) Co., Ltd., introduced that Xinxin Linear has successfully broken the traditional concept that' high-end equipment must use imported parts'.

Climbing high and striving for strength, promoting industrial technology upgrading and value creation

Adapt to the times and adapt to the situation. Since its establishment, Xinxin Straight Line has always anchored innovative development, gathered senior technical talents from various sources, created a complete supply chain resource, promoted the landing and transformation of technological advantages in China, and helped upgrade Chinese manufacturing.

At present, the company has micro rail and standard rail mass production factories in Kunshan and Hai'an, Jiangsu, with manufacturing environments that are superior to industry standard configurations. Its rich, diverse, and highly precise product line not only meets the market's stringent demand for high-precision machining, but also ensures leading production capacity domestically, becoming a solid foundation and driving force for its stable development.

Thanks to the grasp of the opportunities of the times, deep cultivation of core capabilities, and firm implementation of the innovation driven development strategy, Xinxin Straight Line's products not only reach the international leading level in accuracy and speed, but also have significant advantages in price.

Localized production and manufacturing are also our major core competitiveness. With the highly coordinated resource advantages of the upstream and downstream of the Yangtze River Delta, we can ensure the quick and efficient satisfaction of customized product needs and service capabilities of customers. Zhao Hui said that at the service level, the company has built a full cycle support system from demand analysis, scheme design to systematic production and delivery. Whether it is the demand for miniaturized transmission of medical equipment or the high-speed and high load scenarios of electronic production lines, the team can provide customized solutions.

Zhao Hui stated that with a comprehensive service network and rapid response mechanism, Xinxin Straight Line has established long-term cooperation with multiple industry leading enterprises, becoming a trusted partner in the field of transmission technology.

Committed to innovation and global expansion, Xinxin Linear is breaking through industry boundaries, expanding application scenarios, and transforming from a "follower" to a "leader". With the power of technology, it strives to climb higher and become stronger, continuously extending towards the high-end of the value chain. From parts to components, from manufacturing to service, from "price internalization" to "value creation", Xinxin Straight Line, with its unchanged guide rail, helps innovate in the ever-changing industries and application fields, and contributes an important force to the high-end development of the global manufacturing industry.

(From the National Economic Portal - China Economic Network)